Case Study: Turning a Shift Handoff Breakdown into a 35% Productivity Gain

The Problem: Silent Supervisors and Lost Production

A metal container manufacturer in Chicago was facing a serious productivity issue. Two shift supervisors had stopped speaking to one another over personal reasons, and despite repeated attempts, plant management had been unable to get them to collaborate.

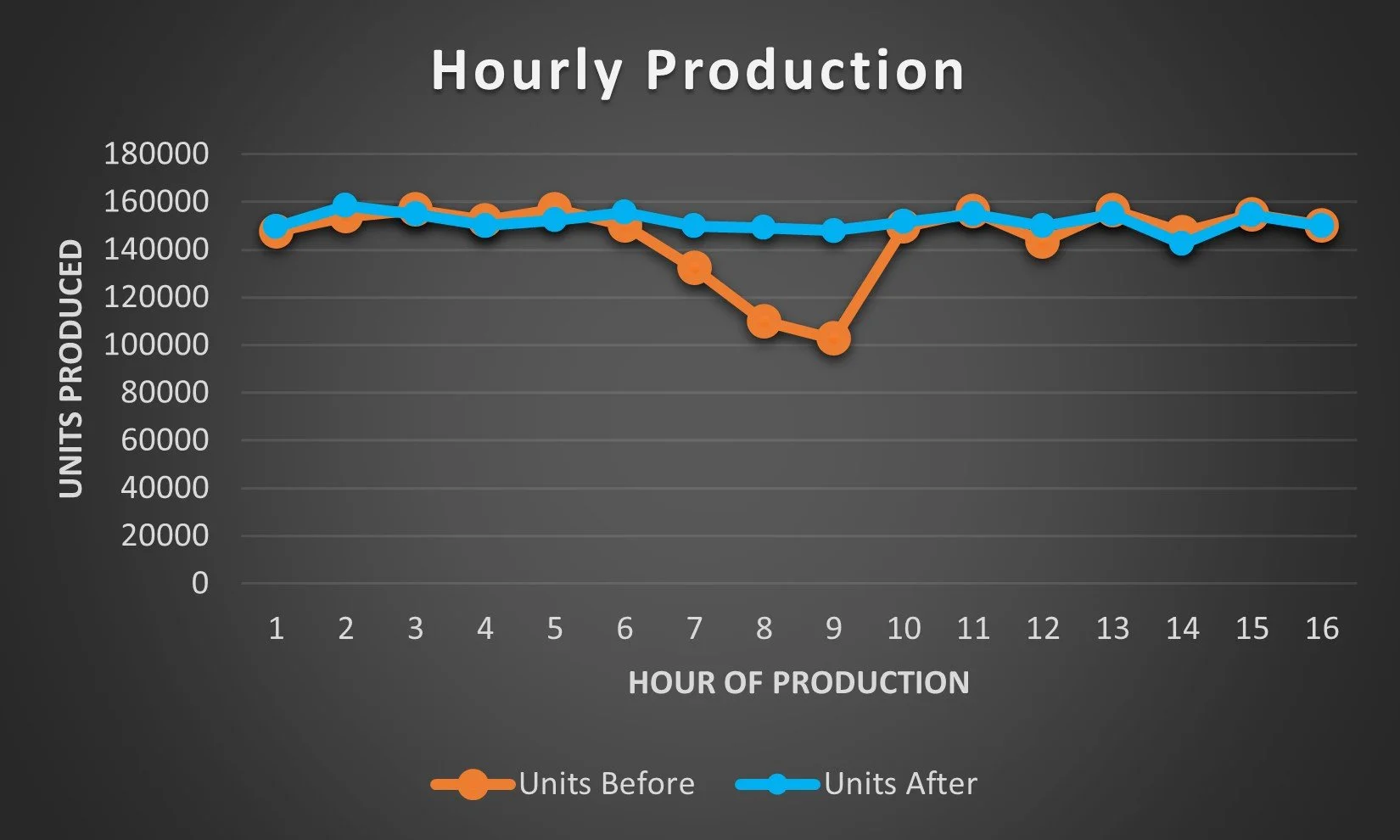

The lack of communication showed up in the numbers. By installing short-interval control, I measured production hourly across 30 machine press lines and found consistent productivity drops:

Last hour of first shift

First hour of second shift

On average, over 100,000 units per day were being lost, which was a staggering gap considering each shift was expected to produce around 1.25 million units in total.

The cause was clear: with no shift handoff process, the oncoming supervisor often assigned operators to presses that were offline for maintenance or unscheduled. As many as 3 operators per handoff were being mis-assigned, standing idle until the floor was walked (if at all).

My Role: Designing Tools to Drive the Right Activity

Plant leadership had tried “telling” supervisors to communicate, but words alone weren’t changing behavior. My role was to design a Management Operating System (MOS) that would force productive communication into the daily routine.

I introduced two tools:

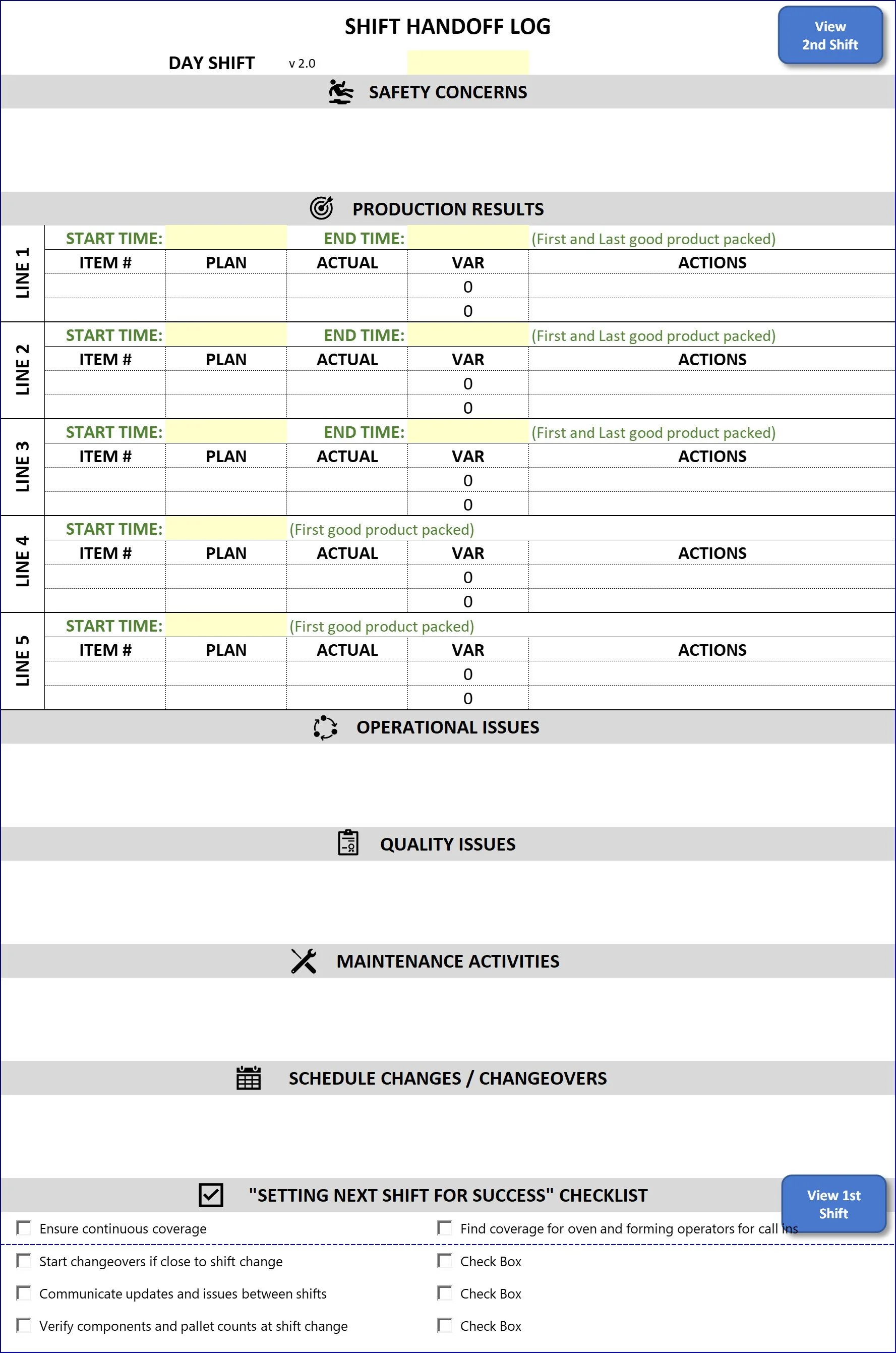

The Shift Handoff Log

The Shift Handoff Walk

Shift Handoff Log – A real-time record of each production line’s status, including:

Preventative maintenance

Production variances vs. plan

Issues and corrective actions

Notes for the oncoming supervisor

This provided a way for these two supervisors to communicate without the uncomfortable necessity of actually talking to each other, so they were more willing to engage with this tool at the start.

This also gave each supervisor a reference to refer to at any point in their shift, memorializing shift by shift activity and performance for future reference.

Shift Handoff Walk – A structured floor walk where both supervisors walked shoulder-to-shoulder reviewing every press line. The departing supervisor showed the state of the floor, and the oncoming supervisor confirmed understanding before taking control.

These tools weren’t paperwork for the sake of paperwork—they were designed to force collaboration where none existed

Results: Immediate Productivity Lift & Cultural Shift

The impact was dramatic:

35% improvement in last hour/first hour productivity

Idle operator mis-assignments eliminated

Noticeable improvements in productivity the very first day the walk was implemented

Daily production meetings became more effective, with supervisors better informed about line conditions

Culturally, the shift supervisors had no choice but to communicate through the log and walk. This ended months of unproductive stalemate that plant leadership had been unable to resolve.

Broader Impact

The success of these tools didn’t go unnoticed. Plant leadership standardized the Shift Handoff Log and Shift Handoff Walk as best practices, with plans to roll them out to:

6 other business units in the same facility

7 additional facilities across the Chicago area

Although my consulting contract ended before rollout, the tools became part of the company’s standard work—a lasting operational improvement.

Insights: Tools Drive Behavior

The key lesson is that tools should be designed to drive activity, not just to capture data. Plant management’s verbal directives hadn’t worked, because they didn’t force action. By contrast, the Shift Handoff Walk required interaction, observation, and accountability.

Productivity improved not simply because of better reporting, but because the right activity—collaboration at shift change—was finally happening.