Case Study: How a Safety-First Start Boosted Engagement and Productivity

Challenge

A food manufacturing client with nearly $100M in sales was struggling with operator fatigue and disengagement on the production floor. Each of the 14 lines required about seven operators, but supervisors frequently had to reshuffle assignments when workers reported soreness, fatigue, or inability to continue in their assigned stations. While leadership suspected this was hurting productivity, they had no data to measure it.

In addition, shift kick-offs were perfunctory. Supervisors shared assignments and expectations, but operators often stood silently, glassy-eyed, waiting to get back to the floor. The meetings weren’t connecting safety, engagement, and performance, they were simply “going through the motions.”

Action

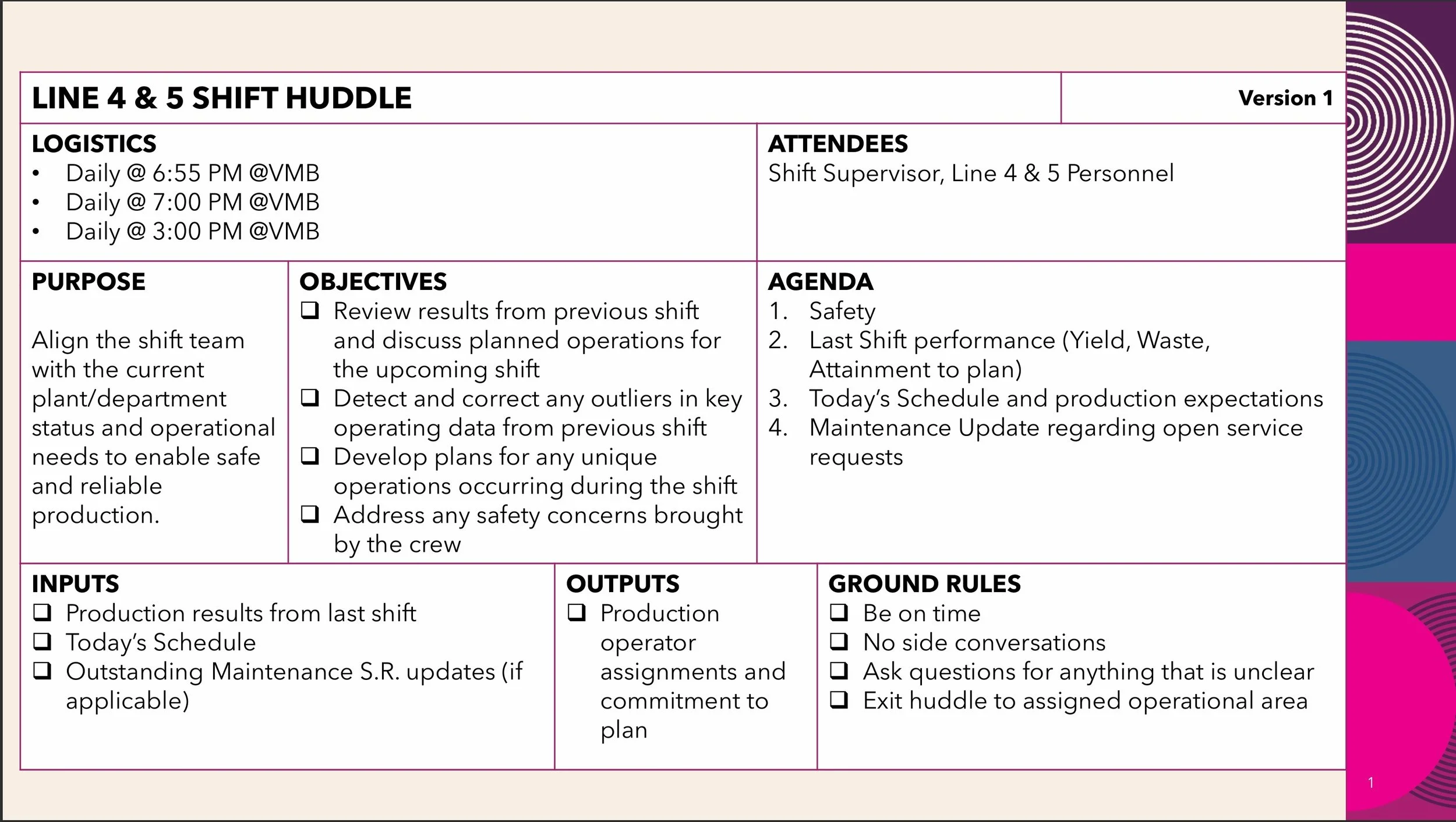

Brought in as an outside consultant, I designed a new Shift Kickoff Huddle process centered around safety and productivity alignment:

10-minute Daily Huddle: Supervisors led operators in front of the Visual Management Board to review assignments, production goals, yesterday’s numbers, and known issues.

Targeted Stretching Routine: While supervisors spoke, operators performed low-impact stretches tailored to their tasks. Hand and forearm warm-ups for dexterity jobs, back and leg stretches for lifting and bending, etc. Drawing on my athletics background, these routines prepared both body and mind for the shift.

Supervisor Training: I coached supervisors on running structured, engaging huddles that encouraged questions and feedback instead of one-way communication.

Importantly, the stretches were not an added burden. Operators were already standing together, the routine transformed idle time into productive physical and mental preparation.

Impact

Within four weeks of implementation, measurable and cultural improvements emerged:

26% reduction in reassignment requests due to fatigue or soreness, keeping top operators in their most impactful roles.

1–3% productivity improvement on affected lines, even in the short trial period.

Engagement breakthrough: Operators who once stood silently now asked questions, shared suggestions, and engaged with supervisors on production goals and Continuous Improvement projects.

Leadership recognition: Executives noted how much more engaged the workforce appeared, remarking that operators seemed to genuinely care about whether they had a successful shift.

Takeaway

This project demonstrated that safety is not a tradeoff with productivity, in fact, it’s an enabler of it. By reframing the start of each shift around warming up bodies and minds, operators not only stayed healthier but became more attentive and invested in the day’s success.

The immediate results were clear in reduced fatigue-related reassignments and modest productivity gains. But the deeper value was cultural: a workforce more engaged, more communicative, and better aligned to drive continuous improvement into the future.