Case Study: Coaching a Rookie Executive Through a $12M CapEx Success

How Structured Mentorship and Project Discipline Helped a Georgia Flooring Manufacturer Avoid $5M in Overruns

Client Overview:

Location: Greater Atlanta, GA

Industry: Building Materials - Flooring

Annual Revenue: ~$250M

Employees: ~600

Project Type: Capital Equipment Installation

Project Value: $12M

Executive Summary:

A flooring manufacturing company promoted a promising but untested executive to oversee a major, high stakes, capital expenditure project. This $12 million initiative involved the installation of a state-of-the-art finishing line intended to double output capacity and reduce waste by ~18%.

The challenge? This new executive had never owned a CapEx project. My role as a management consultant was outlined by the client CEO like this: “Don’t let this project fail. Coach our this new VP how to win.”

I was to provide strategic coaching, implement a disciplined project framework, and ensure this project was delivered on time and within budget.

The result:

✅ Project delivered 2 weeks early

✅ Avoided $5M+ in potential overruns

✅ Line capacity improved by 2.1x

✅ Defect rate dropped by 16% within 90 days

The Challenge

The client had recently acquired a cutting-edge Italian finishing line, with installation scheduled to begin Q1. However, the new VP who was promoted from a finance role with deep experience within the company lacked operational experience, CapEx project management skills, and broad industry knowledge beyond this company. Initial vendor communication was disorganized, milestones were unclear, and key internal stakeholders were not aligned.

Without intervention, the project was on a collision course with:

Delays exceeding 6 months

Line downtime threatening major customer SLAs

Cost overruns due to change orders, rush shipping, and rework

Methodology: CapEx Execution Framework for First-Time Leaders

Phase 1: Project Clarity & Alignment

Objective: Set the foundation for disciplined execution

Define the business case: ROI modeling, cash flow impacts, cost of delay

Identify stakeholders: Plant manager, engineering, finance, EHS, and supplier project leads

Create RACI Matrix: Assigned accountability for every major decision

Establish governance: Weekly standups, monthly steering reviews

Phase 2: Stage Gate Planning

Objective: De-risk the project with control points

We implemented a 5-stage gate model with formal reviews:

Gate

G1

G2

G3

G4

G5

Description

Feasibility & Business Case

Design & Engineering Sign-Off

Procurement & Scheduling

Pre-Installation Readiness

Commissioning & Ramp-Up

Success Criteria

ROI > 20%, all stakeholders aligned

Floor layout confirmed, utilities scoped, permits secured

Long-lead items ordered, vendor project timeline locked

Site prep complete, downtime plan in place

Trial run approved, defect rate ≤ baseline, staff trained

These gates gave us structure and the confidence needed for decision-making.

The rookie executive now had an actionable map to follow with built-in feedback loops to catch risks early.

Step 3: Targeted Recommendations

Based on the findings, we implemented several process and organizational changes:

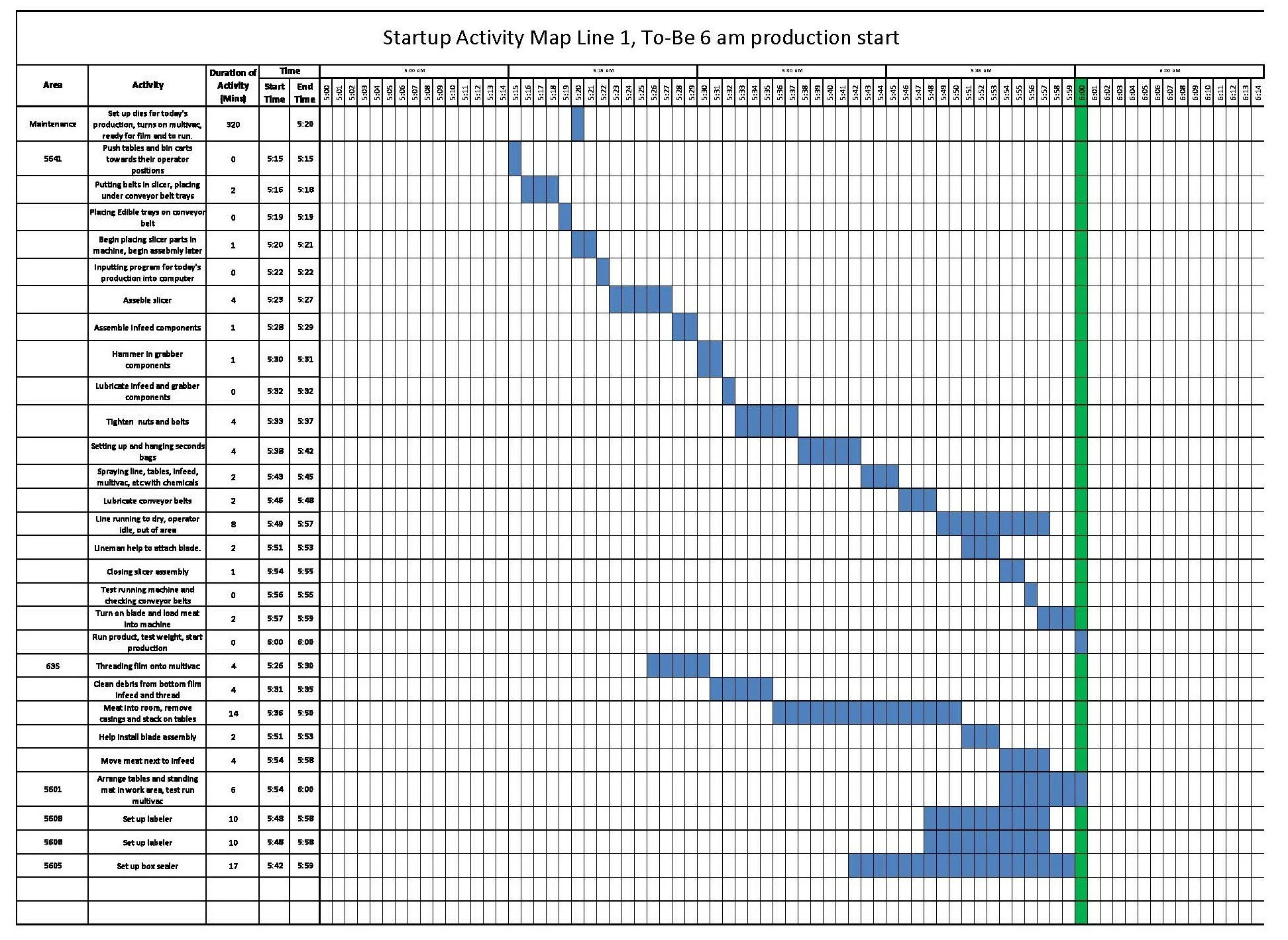

Kitting process: Ensured tools and parts were pre-assembled and readily available, reducing search time.

Parallel tasking: Introduced a second employee during start-up to perform tasks simultaneously.

Published timelines: Created a detailed minute-by-minute start-up procedure, enabling employees and supervisors to monitor progress in real time.

Step 4: Coaching for Collaboration

Recognizing the importance of the human element, we coached managers and supervisors on effective communication. By framing process improvements as a collaborative effort rather than a critique of employee performance, we turned the workforce into active contributors to change.

Results

Our approach yielded exceptional results:

Start-up delays reduced from 52 minutes to under 3 minutes per day.

49 additional minutes of daily production time gained.

$2,000,000 in annualized margin improvement on the highest-margin product.

These outcomes were achieved in just eight weeks!

Insights and Key Takeaways

Data-Driven Decision-Making: Granular KPIs and downtime tracking enabled precise identification of bottlenecks.

Process Optimization: Tools like SMED analysis provided actionable insights to streamline operations.

The Human Factor: Effective communication fostered a culture of collaboration, transforming employees into problem-solvers.

Rapid ROI: A focused and disciplined approach can drive significant results in a short time frame.

The client’s president summed up the impact best:

“If I had known we could be this much more efficient, I would have started this project years ago.”